Tetris in real life.

The last time you opened a box with something you ordered online, did you wonder what route it took to get to you? How many places it visited and how many hard-working hands took care of it? How much effort was put into getting it to you? Then let’s see what a day in the warehouse of an online auto parts store looks like! A lot goes on here. There is a continuous flow of actions, things and elements, just like in the game Tetris. Our goals are to match market expectations and to create the best logistics solutions.

More than 2,000 people already work in our 63,000 m2 warehouse complex. Here you’ll find kilometres of meandering conveyors, millions of boxes waiting in rows for their turn to protect precious products that are about to embark on their journey and, most importantly, a well-organised team of logistics strategists who do everything to optimise processes to your greatest benefit! However, what is most striking is the “hardworking calm”. There is no room for chaos or random actions. All processes are interconnected, so they must be carefully designed and coordinated. This is precisely the most important everyday goal of logisticians and warehouse workers.

When we enter one of the warehouses, the first thing that surrounds us is the energy of work coming from every direction: people moving around, trolleys, automation in operation, the voices of conversations and the metallic sounds of the huge quantity of products that are already “waiting in the starting blocks” to bring our customers’ cars back to life.

As standard, all our warehouses operate in two shifts, depending on current demand and the number of orders from customers. In our warehouses, the full processes of handling orders from our online shop take place: we receive car parts and accessories from our suppliers, verify that they match the orders, then arrange them on the warehouse shelves so that they can later be easily found at the location and quickly dispatched.

WHAT DOES WORKING IN A WAREHOUSE REALLY LOOK LIKE?

“Do you remember the well-known and once very popular game Tetris, in which you had to arrange coloured blocks of different shapes so that there were no gaps between them? Working in a warehouse is a bit like Tetris in real life. It’s a nice association. You have to be able to coordinate everything in such a way as to manage the supply of products in the warehouse and their flow and dispatch in the best possible time, bearing in mind the best possible use of warehouse space.

Every day we think about how to be better than we were the day before. This engages our minds a lot and makes the level more interesting and challenging. However, if we look at such responsibilities as a challenge in a game, each day is fun and a bigger and bigger test to overcome!” – says Marcin Grigoriew, M10 Warehouse Manager.

HE STRUCTURE OF A WAREHOUSE AND THE MOST COMMON PROCESSES

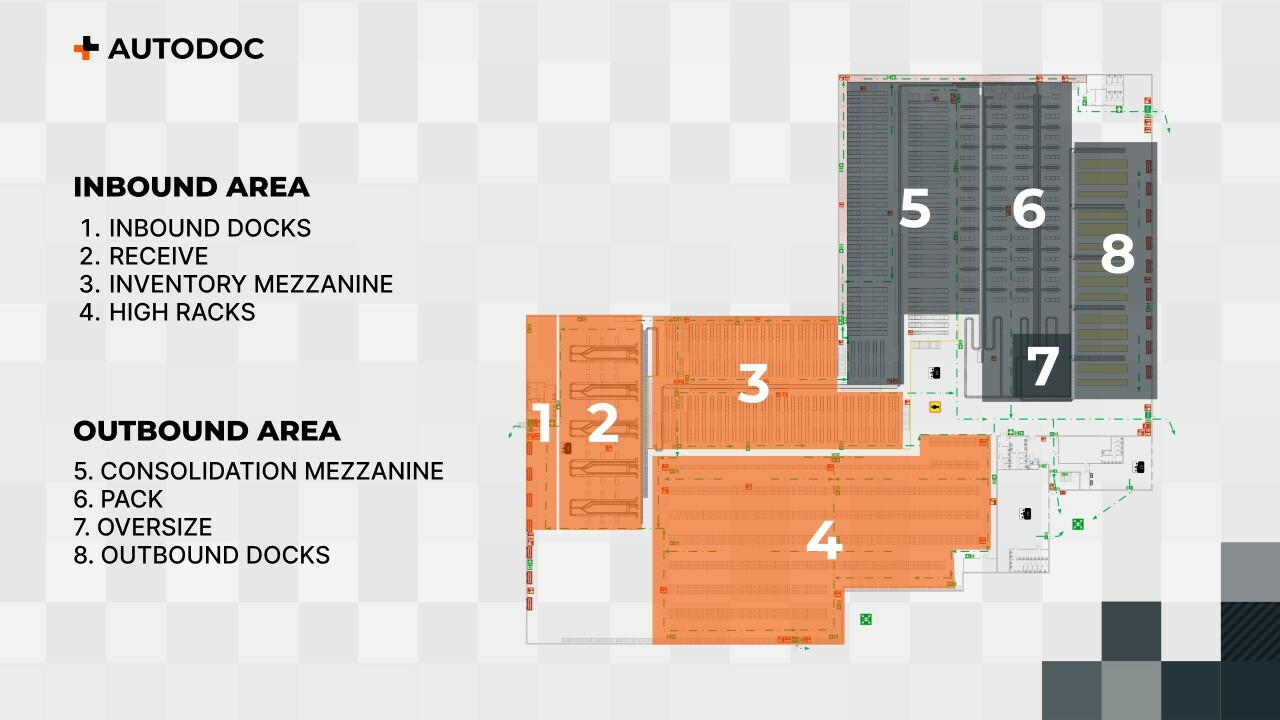

Each warehouse is divided into special zones, which are responsible for different tasks and processes. Depending on which department an employee is assigned to, they will encounter different duties and tasks specific to the warehouse area.

Let’s start by identifying the two most important divisions of the warehouse zone. These are the INBOUND area, which includes the areas and processes of receiving and unpacking goods, entering them into the system and storing them, and the OUTBOUND area, which includes the areas for picking all the items included in one order, packing products into shipping boxes, sorting packages, loading them into containers, and shipping parcels from the warehouse.

GENERAL STORAE DUTIES also take place in warehouses, such as moving goods between facilities, operating warehouse equipment such as forklifts, taking regular inventory of the warehouse, and working with other company departments.

RESPONSIBILITIES AT THE WAREHOUSE

The responsibilities of a warehouse worker largely depend on the specific warehousing processes carried out in a particular AUTODOC facility. In our warehouses, we work with car parts, which have a very diverse range, from small and lightweight components to very large and heavy items such as brake discs or shock absorbers.

Despite the advances being made in the automation of our warehouses, a sizable portion of the processes are still carried out through typically physical activities. Many people prefer physical jobs to sitting still most of the day in an office job. Of course, it all depends on each individual’s personal preferences.

“Our warehouse spaces are sizable and we move quite a distance every day, but I still wouldn’t swap this job for any other. I am not keen on desk work. I like to work as a part of a team and in constant motion. I was even offered a position in our company’s office, but I didn’t take it because I wanted to work with people in direct processes. This is what motivates me, this is the style of work I love! I started at AUTODOC as a basic warehouse operator , then became an Instructor and now I am developing myself as a Team Leader. What’s great about our warehouses is that you have the chance to adapt the type of work you do to your preferences and your character. It’s best to go through all the processes and explore all the choices. There are really a lot of opportunities here! – Yuliana Kalinova, Shift Leader M13.

In the photo below: Yuliana Kalinova, Shift Leader M13.

Of course, the majority of work in the warehouse involves lifting, moving, positioning or repositioning products to different locations, but for these heaviest operations, machinery, automation, or lifting vehicles are used, which make things much easier for workers performing manual tasks.

“My work has always had to do with performing physical tasks. After all, it is normal in a warehouse to have to move things, lift things, change their location, sort or pack them. Physical work, however, does not tire me out. I like doing it because I’m skilled at it and I’m in good shape. In addition, I like to have “peace of mind” after work. I perform specific duties and after work I don’t have to worry about anything.” – says Sebastian Stachowski, Inbound Operator.

IMPORTANT SKILLS TO HAVE FOR WAREHOUSE WORKERS

The profession of warehouse worker has evolved a lot over the last few years. Today’s warehouse workers also need computer skills and knowledge of basic logistics. Since we deal with logistical operations at each stage of warehouse work, it is desirable for the employee to have logical thinking skills, and to be meticulous and well-organised in their work. Finding new solutions and constantly looking for the best use of space requires perceptiveness, reflexes and poise, just like a game of Tetris.

In our teams, it is als very important to have good interpersonal skills in order to communicate and cooperate efficiently with leaders, managers, and other members of large teams.

Despite the fact that we work with goods that vary in terms of size and weight, our warehouses also have plenty of female workers, who thrive in departments where they can use their manual dexterity, precision, and speed, for example by packing products for dispatch, or in leadership positions where they can showcase their communication skills.

“I am a very open, talkative, and approachable person. That’s my character and I think I use it very well in my job. I am currently a Warehouse Operator in the goods receiving department and I am very happy to have been given this opportunity to develop myself. I enjoy physical work, so I can combine the style of work I prefer with working with people. I like to support them in their daily work and advise them in various situations that require it.” – says Aneta Łosińska, Warehouse Operator.

FORKLIFT OPERATOR

The tasks of a forklift operator are very diverse and depend on the specific processes of the warehouse facility. The main duties of a forklift operator include controlling the vehicle and transporting loads. The forklift operator steers the forklift, controls the equipment, positions the forks and the platform, secures the load, and transports it to the designated location.

The operation of the forklift itself is not complicated; the rules are similar to those for driving a passenger car. You don’t need a lot of experience to learn to drive it quickly and efficiently.

QUALITIES OF A FORKLIFT OPERATOR

It is essential to have a forklift licence and a current medical certificate issued by an occupational physician in order to take up this position. Forklift drivers should have excellent hearing, eyesight, and full psychomotor skills, be able to react quickly, and have excellent precision and coordination. In addition, it is good for a forklift operator to be able to easily estimate distances. This skill is very helpful when determining the distance between racks or pallets, which is especially important when operating forklifts in a high bay storage area. It is very important for a forklift operator to be a responsible and accurate person, as manoeuvring the vehicle in the warehouse racking area requires a great deal of focus and precision. Operators must be composed and perceptive, as they are also responsible for the safety of other people in the warehouse.

“I considered taking up a job as a forklift operator as quite a challenge. Many people didn’t believe I could handle such a demanding and responsible position. It motivated me even more to achieve the goal I had set for myself. I love challenges! I’m proud of myself and can’t even imagine changing to another job now. I am currently taking part in a training course for a higher category of forklift licence. I am very pleased and appreciate that AUTODOC has invested in the development of my competences. It gives me wings! Do I get tired of having a lot of responsibility? Absolutely not! If you have a predisposition for such a profession, at some point it becomes a natural part of the job. You just have to be humble and cautious, and the rest is perfectly ‘manageable’. It’s already in my blood.” – Joanna Bronicka, Forklift Operator, answers, with a smile.

In the photo below: Joanna Bronicka, Forklift Operator.

I HAVE NO EXPERIENCE, AM I LIKELY TO GET A JOB?

“We encourage all potential employees to apply to work with us, even if they have no warehouse experience. We are particularly keen to work with people who are committed to their work, enjoy learning, are cheerful, and value working with other people. Our system of initial instructional training and the daily support of leaders and instructors will guarantee you the necessary package of knowledge and skills required for a particular warehouse position.” – assures Rafał Stankiewicz, Instructor of M13 Warehouse.

WHY DO PEOPLE WANT TO WORK WITH US?

“I can recommend working in logistics to anyone who finds it important to feel secure and stable in their job. I’ve worked in different companies, but this is the first place where I feel valued. I have an employment contract for several years, free transportation to work, and I do not feel anxious when my supervisor approaches me. I feel emotional comfort. In my previous job I didn’t have any opportunity for development. Here I have everything that’s most important to me.” – says Yuliia Kryvonos, Warehouse Operator.

“We give our employees the opportunity to develop not only in the position where they start, but we have many examples of career paths where warehouse employees have taken up managerial positions in other departments. When we have so many committed employees with diverse qualifications, it’s a pure pleasure to see them combine their skills together into a single synergy of success and compose a common daily Tetris workspace. It’s a true eclecticism of cooperation” – says Magdalena Dziechciowska, People Partner.

OCCUPATIONAL SAFETY AND SUSTAINABLE DEVELOPMENT

Huge warehouse areas and large numbers of employees also represent a major challenge for occupational health and safety services. Increasing storage areas and adapting workplaces from the point of view of ergonomics, safety and comfort for employees is a series of extensive measures to be planned and implemented.

“We carry out safety control audits at all our warehouses on a daily basis. It is important for us not to focus only on procedures, but to focus first and foremost on people. We have direct contact with them every day, educate them on correct attitudes, give them numerous corrective hints and do everything we can to nullify potential risks. Every year, we also carry out tests on working environment factors. We check that limits are not exceeded. Being fair to the employees and ensuring that their working standards are correct is of the utmost importance to me. It is my service to the people, my colleagues, with whom I work every day. For me, they are not anonymous individuals. It’s a matter of responsibility for other people” – says Krzysztof Pawlak, Health and Safety Officer.

Green logistics, i.e. doing business in such a way as to have the least possible impact on the environment, is also very important to us. We feel responsible for analysing the supply chain in detail in order to take measures to reduce potential risks to the ecosystem as much as possible in the course of our organisation’s logistical and strategic operations.

Being a tech company, we are proud of using technology to embed sustainability into our digitised supply chain processes. As ESG – Ecological, Social, Governance – is moving to the top of our agenda for all our warehouses, we are optimising transport flows that will significantly reduce transport-related CO2 emissions. Already today we are using sustainable and eco-friendly alternatives to plastic materials in our packaging. And over the course of the next few years we will be raising the industry standards in logistics even more.

A priority for building AUTODOC’s advantage in the market is the structure of our supply chain and warehouse infrastructure worldwide. In order to perfectly arrange these logistical elements, it is necessary to strategically plan the flow network of all the organisation’s structures and cooperation with suppliers. The result of such activities is the development of the AUTODOC DNA strategy document and realisation and opening later this year of further warehouse investment in the Czech Republic (27,000 m2), which will have a key impact on the efficiency of the entire AUTODOC Group and the achievement of the best delivery times.

“Agile and effective management of logistic areas, similar to in the game Tetris, is a state in which we strive for better and better performance and our goal is to achieve a perfectly ordered fractal structure, like the one we observe in the cosmos.” – says Marc Pick, General Manager of AUTODOC PL.

We hope that with this article we have been able to explain at least a little bit and present the logistical processes in which our warehouse employees are involved and which are the basis for the functioning of our supply chain management.

In the next article, we will present the essence and strategic activities of the Maintenance Department and the Facilities Department, a clever shadow army that is not visible at first glance, but plays a key role in the logistics operations that are the basis for the safety and operation of our entire organisation.

Related stories

Education As A Determining Factor For Career Development

The development of our employees is a strategic priority for the company. Processes, technologies and tools change and evolve so rapidly that only con...